Carbon Layer Infused Meltblown Machines

CLIMB™ filter technology is a patented (9,981,211) process for infusing layers of Granulated Activated Carbon (GAC) or other particulates into Meltblown filter cartridges.

Now you can have all the advantages of polypropylene gradient filter with the chlorine removal offered by activated carbon!

CLIMB™ technology creates a filter that has discrete layers of meltblown with alternating layers of carbon

- Keeps inventory costs low

- Control the quantity and quality

- Helps to manufacture products tailored to each customer’s individual needs.

Meltblown Filter Cartridge

The activated carbon can be introduced into the filter at any stage of the winding process or in areas of the filter where desired. The amount of meltblown separating the carbon and the amount of carbon separating the meltblown can be increased or decreased with state-of-the-art recipe driven software.

The carbon is accurately metered and secured between the layers of meltblown. This method of filter manufacturing creates a filter with very high flow rates, minimal pressure drop, and high filtration efficiency.

Results

The result of this manufacturing process is a meltblown gradient density filter cartridge containing carbon with an extremely high carbon surface area with very low initial pressure drops. It eliminates the problems of fouling and face-loading of extruded carbon block filters.

By having several layers of meltblown near the center or core, it also eliminates the need for pre-wetting or washing carbon fines from the filter prior to use.

CLIMB™ Filters

CLIMB™ filters can be heavily saturated with carbon to the point where the meltblown fibers make up only a small fraction of the total filter weight. CLIMB™ Technology was developed by Southern Coastal Machinery, Inc. in Braselton GA.

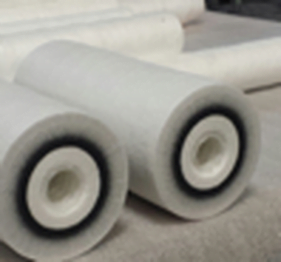

4.5 “ OD (CLIMB™ FILTER)

BCFW CLIMB™ filter machines can produce the standard 2.5” filter. The 4.5” (aka “Big Blue”) which is pictured above, was produced on our BCFW machine. Our BCFW machines can produce meltblown cartridge filters with carbon located at any point within or throughout the entire filter using CLIMB™ technology.

CLIMB™ LAYERS DECONSTRUCTED

The CLIMB™ process creates discretely metered layers of meltblown and discretely metered layers of carbon within each full stroke of the machine.

CLIMB™ CARBON LAYERS

Granulated Activated Carbon (GAC) is infused into the polypropylene (PP) Meltblown layers and permanently adheres to the PP fibers. The GAC is uniformly disbursed and will not migrate.

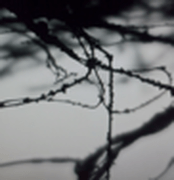

CLIMB™ Technology Up Close

The images here are from our digital microscope. As you can see from the first image, the carbon particles are uniformly disbursed and evenly coat the PP fibers. Having the appearance of “barbed wire” the carbon particles can be seen attached to the exterior surface of the fibers.

CLIMB™ filters offer higher surface area and greater void volume than carbon block filters. The result is a depth filter that has a minimal initial pressure drop, high flow rates, and long life.

The CLIMB™process exposes more of the GAC surface area than other types of carbon filters by creating space and open area. The particles do not clump together or migrate, so less carbon can be used to achieve the same chlorine removal as extruded carbon block filters.

A typical carbon block filter will contain upwards of 900 grams of carbon, compared to a CLIMB™ filter containing 80 grams.

GAC INFUSION

The fibers in the photo above are approximately 3-5 microns in diameter and are completely coated with carbon nano-particles. Miles of surface area is created with only a few grams of material.

The VARIABLE ADD-ON

The CLIMB process is variable and can completely coat the PP fibers, or it can be limited to only partially coating the fibers. The photo above shows the uniformity of coating even at very low levels.

Competitive Product

The photo above is from a competitive product claiming to have carbon in the melt blown filter. As you can see, all of the carbon is contained within the PP fibers leaving none of the carbon exposed. These filters are totally ineffective.

200X MAGNIFICATION

The fibers in the photo above are approximately 3-5 microns in diameter and are completely coated with carbon nano-particles. Miles of surface area is created with only a few grams of material.

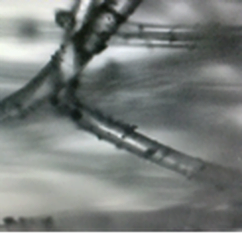

600X MAGNIFICATION

The C.L.I.M.B. process is variable and can completely coat the PP fibers, or it can be limited to only partially coating the fibers. The photo above shows the uniformity of coating even at very low levels.

1000X MAGNIFICATION

The photo above shows two fibers that are approximately 3 microns, coated with carbon nano-particles. The surface area of the carbon remains exposed.

SCM continues to invest in research and technology to maintain its status of providing the most state-of-the-art melt blown filter technology in the world and has recently been awarded a new Patent for incorporating particles into Meltblown, such as carbon, for enhanced filtration. (Patent No. 9,981,211) Address : 1101 Hwy 124 Hoschton, GA 30549

SCM continues to invest in research and technology to maintain its status of providing the most state-of-the-art melt blown filter technology in the world and has recently been awarded a new Patent for incorporating particles into Meltblown, such as carbon, for enhanced filtration. (Patent No. 9,981,211) Address : 1101 Hwy 124 Hoschton, GA 30549

Contact :

Phone: +1(404)316-3622

Email: mcpelham@gmail.com

Latest News

- UGAfibers Laboratory Expands Capabilities for Nonwoven and Protective Fabrics Industry December 21, 2024

- The Ultimate Guide To Buying And Using A HEPA Filter April 20, 2022

- The New Nonwovens’ Golden Fleece meltblown fabric for mask December 12, 2021

- Melt Blown Non Woven Fabric – An Overview December 6, 2021