BCFW Machines

Batch Cartridge Filter Winder Machines

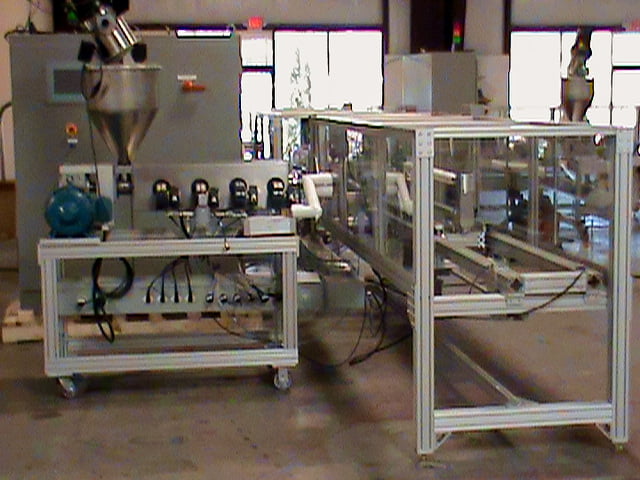

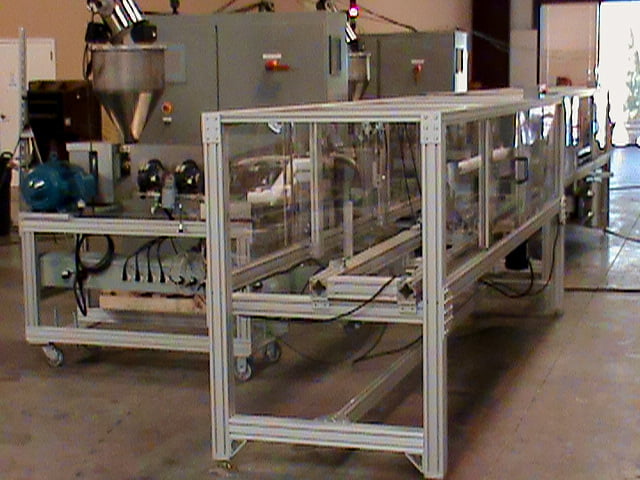

The BCFW is designed to manufacture high performance Melt Blown Cartridge Filters, including Carbon-impregnated Cartridge filters, at a fraction of the cost of our CCFW lines.

Do you want to sell a Melt Blown cartridge filter that exceeds the performance of all other Carbon impregnated Cartridge Filters?

The BCFW is the perfect size for short runs so you can eliminate the problem of not having the inventory that your customer urgently needs.

With the BCFW you can keep inventory costs low and control the quantity, quality and delivery of your products tailored to each customer’s individual needs.

The new BCFW with CLIMB Technology Carbon-impregnated Cartridge filter machine will allow you to become an industry leader with an equipment lease payment lower than your monthly inventory costs.

The Batch Cartridge Filter Winder can make 2.5″ to 4.5 ” diameter cartridges up to 50″ long, with or without cores and up to 48 individual zones.

Batch Cartridge Filter Winder Series

The BCFW series can be easily upgraded to CLIMB technology, a patent pending process created in Braselton, GA by PMI America, for granular activated carbon impregnation.

The BCFW series is ideal for short product runs, or multiple product runs for diverse SKUs to be made at the same time, and is also ideal for research and development.

CONTINUOUS MELT BLOWN CARTRIDGE FILTER MACHINES

MADE BY PMI AMERICA, INC.

CE Compliant Controls

Touch Screen and recipe driven software

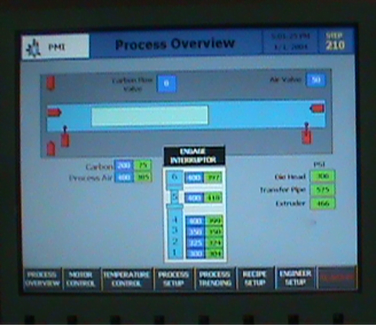

We have developed a very easy to operate, yet flexible Touch Screen Control System with Recipe storage for multiple products.

Our control cabinets are NEMA 4 and all components are CE certified, as well as the cabinets themselves.

Operator interface consists of loading and unloading mandrels or cores, and pressing the start button. It is very simple for the operator.

Your Process Engineer can upload a pre-set Recipe for the multiple products. The Recipes will have all of the pre-determined set-points for all the variable parameters, which include Die Pressure, Air Pressure, DCD, Rotational Speed, Linear Speed, and many others that are required to make a particular filter. Once the Recipe is uploaded, all the operator has to do is press the Green Start Button!

CE Compliant Controls Screens

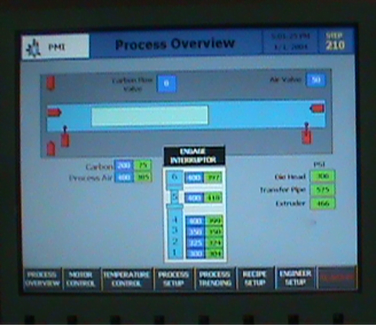

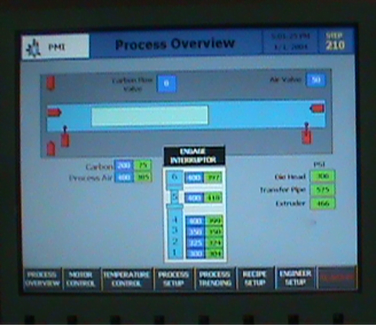

PROCESS OVERVIEW SCREEN

This screen shows all critical parameters of the process on one screen. When operating in Automatic mode, this is the primary screen.

MOTOR CONTROL SCREEN

This screen allows manual control of each motor in the system. This is typically used when performing R&D or when the process engineer wants to drive manually.

RECIPE SCREEN

The Process Engineer will program all the set-points of the recipe into this screen that is then saved to be recalled for future production.

SIMPLIFIED MANUFACTURING USING MODERN TECHNOLOGY

“Simplicity” is what we had in mind when we approached the design of our new BCFW Meltblown Cartridge Filter Winders.

All of our machines 3D modeled in the latest CAD-CAM software.

Built using standard “off the shelf” electrical components.

Siemens PLC and Touch Screen Control

CE Certified

Three-Light Alarm Tree for “under temp” or “High Pressure” alarms.

Filters can be made with or without core

Makes Meltblown Filters 2.5” Dia. up to 4.5” Dia. and up to 50” Long

Go to Other Machines Details

PMI AMERICA Melt Blown Cartridge Filter Machines and Technology

CCFW Machines For Mass Production of Melt Blown Cartridge Filters

BCFW Melt Blown Cartidge Filter Machine with CLIMB™ Technology

CCFW Machines For Mass Production of Melt Blown Cartridge Filters

BCFW Melt Blown Cartidge Filter Machine with CLIMB™ Technology

SCM continues to invest in research and technology to maintain its status of providing the most state-of-the-art melt blown filter technology in the world and has recently been awarded a new Patent for incorporating particles into Meltblown, such as carbon, for enhanced filtration. (Patent No. 9,981,211) Address : 1101 Hwy 124 Hoschton, GA 30549

SCM continues to invest in research and technology to maintain its status of providing the most state-of-the-art melt blown filter technology in the world and has recently been awarded a new Patent for incorporating particles into Meltblown, such as carbon, for enhanced filtration. (Patent No. 9,981,211) Address : 1101 Hwy 124 Hoschton, GA 30549

Contact :

Phone: +1(404)316-3622

Email: sales@southerncoastalmachinery.com

Latest News

- UGAfibers Laboratory Expands Capabilities for Nonwoven and Protective Fabrics Industry December 21, 2024

- The Ultimate Guide To Buying And Using A HEPA Filter April 20, 2022

- The New Nonwovens’ Golden Fleece meltblown fabric for mask December 12, 2021

- Melt Blown Non Woven Fabric – An Overview December 6, 2021